For the next in our series of Q&As with our Head Technical Engineer, Russell Churchill, we asked him to explain what is hard water, and why water softeners are needed.

What is hard and soft water?

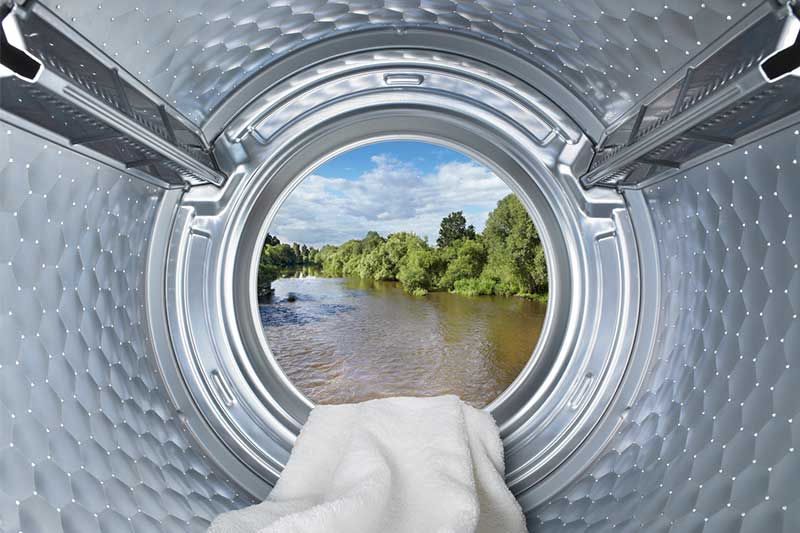

Even though most of the water that comes from our taps is processed before reaching us, it will still contain some particles of where is was sourced from. Most water runs off hillsides and through rivers, and as it works its way down, some of the minerals from these rocks stay in the water, such as calcium from limestone. If there is a high concentration of particles and minerals in the water it is considered to be “hard”, and with less minerals it is considered “soft”.

What issues does hard water cause in dishwashers?

Soft water mixes better with detergents, and hard water causes limescale to build up. Generally, dishwashers need water that is free of any deposits to enable the chemicals to effectively do their job correctly. These deposits (limescale) can stick to internal components such as pumps and elements, leading to premature failure.

What issues does hard water cause with washing machines?

The issues with hard water and industrial machinery is the same across the range, with build-up of scale on elements and pipe work. And, like with dishwashers, the effectiveness of the detergent for washing machines is compromised by the minerals in the water, causing poorer wash results.

What is a water softener?

A water softener removes the calcium and impurities from the water before the water enters the critical components of the machine. In effect, it is a filter that can be cleaned periodically, either automatically or manually, to ‘soften’ the water and give the best ongoing results.

How does a water softener work?

The hard water is passed through a chamber of resin beads that are attracted to the calcium deposits in the water, and these push out sodium ions instead, which are present in the resin. This softens the water. Once the concentration of calcium build-up in the resin is too high, the resin needs “regenerating” by flushing it with salt water. This removes the calcium build up in the resin, and recharges the resin with sodium – this process is called “Ion Exchange”.

What is the difference between an internal and an external water softener?

An internal water softener is built into the appliance, and the regeneration process happens automatically during normal use. The only noticeable change is possibly a few minutes added to the overall cycle time. The regeneration intervals are set at installation and servicing to match the water hardness of each individual site.

With an external softener, this sits between the water supply and the machine. The customer has to flush or “regenerate” the softener periodically to ensure the water is as clean as possible – although automatic external water softeners are available.

What is the difference between a manual and an automatic water softener?

With a manual softener, the regeneration process is carried out fully by the user of the machine, whereas an automatic softener can be preset to run at specific times to keep the resin clear. With an automatic water softener, the only customer input is to make sure the salt reservoir is kept topped up.

What is the benefit of a water softener vs using a descaler?

In simple terms a water softener will prevent a scale build up in the first place, as the main particles that cause build up are primarily calcium based. In this case descaling will not be needed. It’s almost like not needing a raincoat and umbrella by not going out in the rain in the first place!

Thank you, as always, to Russell for this Q&A. If you have found it interesting, and would like any more information on this, or to understand how JTM Service can support you, please contact us on 0113 2572221 or service@jtmservice.co.uk