We asked Russell Churchill, our Head Technical Engineer here at JTM Service, to advise on the key factors behind effective cleaning. In this Q & A, he explains how time, temperature, chemicals and mechanical action interact in the laundry cleaning processes.

What is “The Washing Process”?

The Washing Process explains how cleaning works in a dishwasher or a washing machine – in fact, it is applicable for all cleaning, whether it be mopping a floor, wiping a surface, washing up in a sink or laundering linen.

It is important to realise that cleaning effectiveness is directly proportional to the relationship between certain factors.

What are the key factors that drive good cleaning performance?

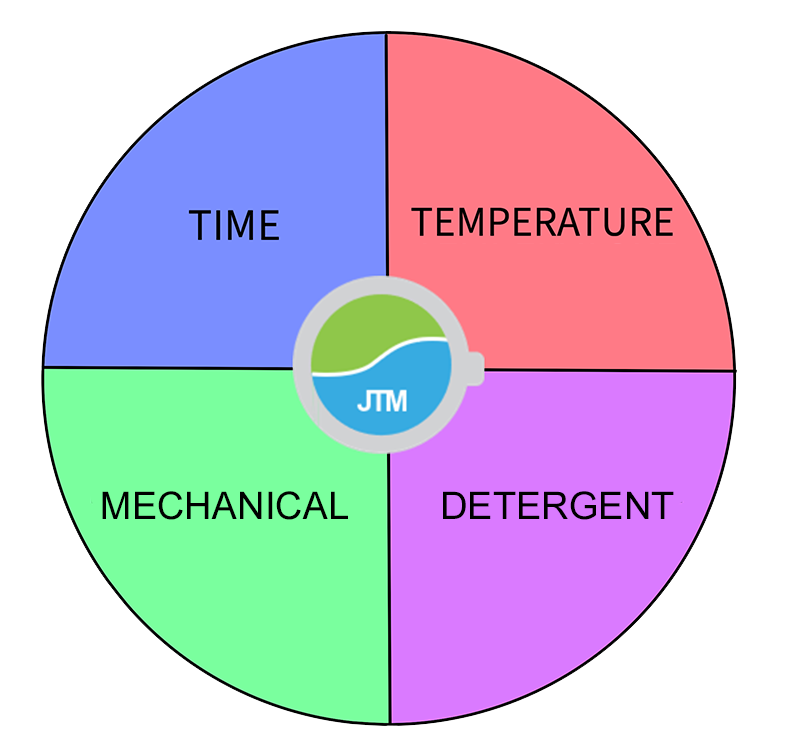

Cleaning effectiveness is directly proportional to the relationship between:

- Time

- Temperature

- Chemical action

- Mechanical action

- Water

If any one of these key factors is reduced, it will need to be compensated for by an increase in one or some of the others. These factors can be represented in a circle to illustrate how the individual factors compensate for each other.

The illustration to the left shows that, when each of the key factors are of equal proportion and the process for washing the items is followed correctly, it is likely that the laundered item should be clean and stain free. An imbalance or decrease in one of these variables must be compensated by increasing one of the others to prevent poor wash results.

Why is it called WATCH?

Another way of stating this is that effective laundry processes are dependent on the acronym WATCH:

- Water quality

- Agitation of the washer extractor

- Time of the wash cycle

- Chemical concentration

- Heat of the wash programme

The elements highlighted work in harmony. If any of the components are increased, the other elements of the circle can be decreased and still give the same results. So, for example, if the chemicals added to a wash cycle are increased, the temperature does not have to be as high, nor does the time or mechanical action. (Note – if thermal disinfection is required, the temperature should reach and maintain the required temperatures for this).

Similarly, if the temperature and time are increased, the amount of chemical does not need to be as high.

How does this work with a commercial washing machine?

In a cottons wash cycle, as the fabric is quite hard wearing, the water level is lower which helps increase the mechanical energy. The temperature is also higher, and that allows the cycle time to be reduced. But in a delicates cycle, the fabric is less tolerant to the mechanical energy and heat. In these cycles, the water level is much higher and the time is longer to counteract this.

Generally, the heat and mechanical actions on machines are preprogrammed into the cycles by the manufacturers, However, at JTM Service, we can tailor these to specific requirements and custom write programmes (where the machine software enables this).

How does this work with a commercial dishwasher?

The process is generally the same for both Laundry and Dishwashing, with the mechanical action in the dishwasher being created by the water spraying out of the arms.

In a dishwasher, if you are using lower temperatures, then this can be compensated for with a longer cycle time.

Thank you to Russell for this Q&A, we hope this is helpful! And if you would like to discuss anything raised in this Q&A, or understand how JTM Service can support you, please contact us on 0113 2572221 or email service@jtmservice.co.uk